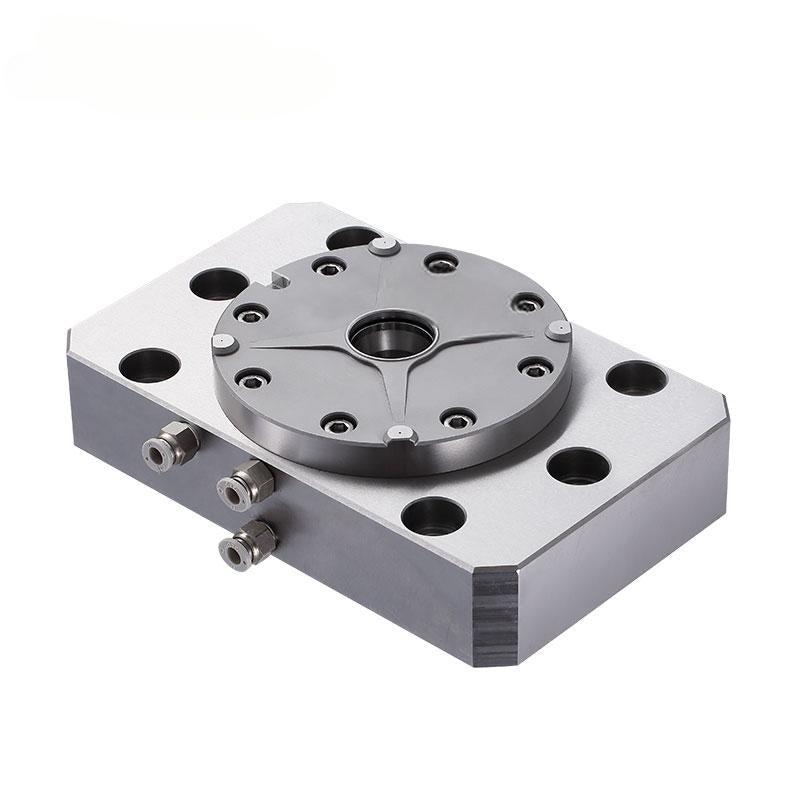

Single Zero-Point Positioning Chuck

We specialize in high-precision CNC machining and die casting, supporting tolerances down to ±0.01 mm.

Our ISO 9001 and ISO 13485 certified facilities provide in-house inspection, engineering support, and DFM review to ensure consistent quality.

We support fast prototyping to low- and mid-volume production, with strict confidentiality for all customer designs and data.

-

Contact Us

Our single zero-point positioning chucks are high-performance clamping modules designed to standardize your CNC machining interface. Ideal for 5-axis machining, automated cells, and rapid prototyping, these units eliminate traditional alignment times with "click-and-lock" workpiece changes in seconds, delivering instantaneous, repeatable, and rigid connections that transform your production efficiency.

| Item | Capability |

| Component Type | Single Zero-Point Positioning Chuck |

| Repeatability | < 0.005mm |

| Pull-in Force | Up to 15kN (With Turbo boost) |

| Static Holding Force | Up to 35kN - 50kN |

| Lifting Capacity | 150kg pallet lift-off / 1mm point contact |

| Material | Hardened Stainless Steel / Tool Steel |

| Actuation Pressure | 6 bar(0.6MPa) (Pneumatic) |

| Surface Hardness | 58 - 62 HRC |

-

95%+ Reduction in Setup Time: Load fixtures outside the machine to keep the spindle running.

-

Standardized Interface: One chuck fits all your fixtures via a unified pull-stud system.

-

Compact Footprint: Low-profile design to maximize your machine's Z-axis clearance.

-

Process Stability: High holding forces ensure vibration-free machining even under heavy loads.

- Long Service Life & Low Maintenance: Resists wear, corrosion, and deformation, ensuring stable performance over 100,000+ clamping cycles with minimal maintenance.

-

5-Axis Machining Centers: Centralized clamping for complex geometry access.

-

Mold & Die Manufacturing: High-accuracy repositioning for multi-stage milling.

-

Automation & Robotics: Standardized interface for robotic pallet loading.

-

EDM & Grinding: Precision clamping in corrosive or specialized environments.

Wide Compatibility

Compatible with most mainstream CNC machine brands (e.g., Haas, DMG MORI, Mazak) and standard clamping stud systems. Supports both manual and automated operation modes for flexible integration into existing production lines.

Custom baseplate configurations and 3D CAD files are available upon request.