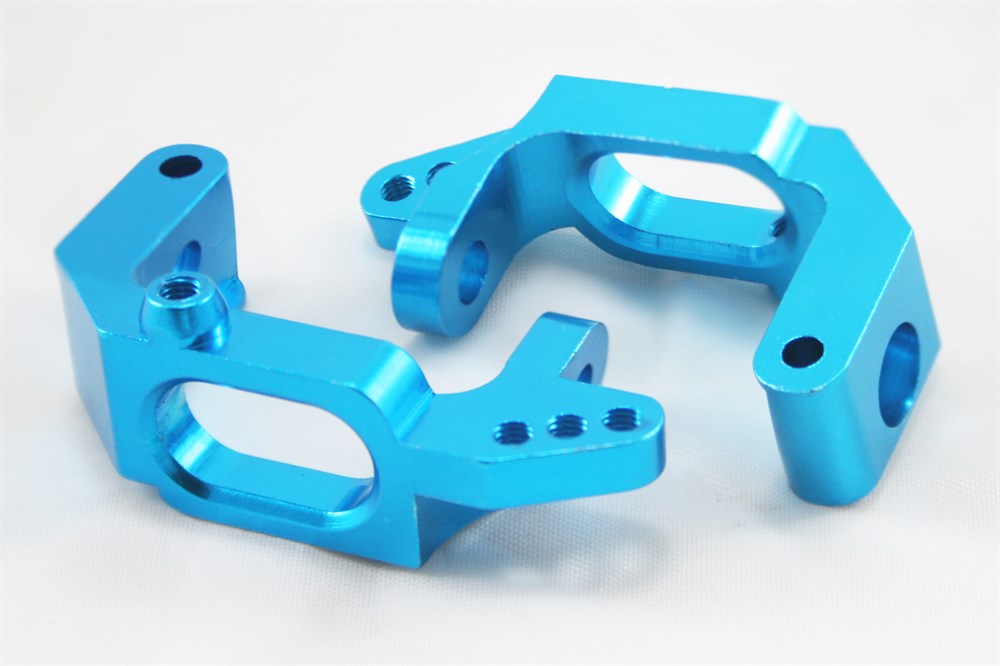

Custom Precision CNC Milling Service

Specialize in pushing the technical boundaries of CNC milling. Able to handle designs requiring a minimum wall thickness of 0.5mm and utilizes fine tools down to a 0.5mm end mill size. Trust our expertise for your most intricate and demanding parts.

Why Choose XY-Global for Custom Presicion CNC Machining?

When your project demands uncompromising precision and speed for complex components, XY-Global is your trusted manufacturing partner.

- Certified Precision: Achieve perfect fit and function with tolerances as tight as ±0.1um, ensured by our ISO 9001:2015 and ISO 13485 certifications.

- Accelerated Development: Turn your design files into a Rapid Prototype in as little as 1 Day, keeping your product development on the fastest track possible.

- Unrivaled Flexibility: Leverage our extensive selection of 45+ Certified Materials and 13+ Finishing options, with the freedom of a Risk-free MOQ of 1 PC.

- Guaranteed Reliability: Rest assured knowing 99% of parts are delivered on-time and to-spec, minimizing delays and maximizing your project success.

From Design to Delivery: Your 4-Step Instant CNC Machining Experience

Upload CAD Files & Receive Instant Quote

Upload your 3D CAD files to our highly secure platform and our AI-driven system analyzes geometry, material, and volume in real-time, generating a detailed final quote in under 60s.

Choose Process & Get DFM Feedback

Select your ideal material from our range of 45+ metals and engineering plastics, and customize machining options, including 3/5-Axis Milling and precise surface finishes.

Order Online & Production Kickoff

After confirming the final design specifications and quote, complete your order payment conveniently and securely on our encrypted platform. The moment payment is processed, your project task is instantly routed to our smart manufacturing facility.

Quality Control & Rapid Delivery

Every finished parts undergoes stringent, industry-leading Quality Control (QC), including high-precision dimensional checks using a CMM (Coordinate Measuring Machine) to guarantee every part meets your requested micron-level tolerances.

Online CNC Milling Service for Custom Machined Parts

CNC Milling Materials

At XY-GLOBAL, our CNC milling is capable of handling an extensive spectrum of materials across virtually every industrial category with ±0.01μm tolerance and Ra 0.8µm, from easily machinable aluminum and soft plastics to challenging aerospace-grade titanium and high-hardness tool steels.

*For materials not listed here, please contact us directly.

Aluminum

1050, 1060, 2024, 3003, 5052, 6061, 6082, 7075, 7050, A356

Stainless Steel

SUS 303, SUS 304/AISI 304, SUS 316L, SUS 440C, 17-4 PH / SUS630

Copper & Brass

C110 (Electrolytic Copper), C360 (Brass), C17200 (Beryllium Copper)

Other Metals

Titanium:

- Grade 2 (Pure Ti),

- Grade 5 (Ti 6Al-4V)

Alloy Steels:

- 4140,

- 4340

- A2/D2 (Tool Steel)

Superalloys:

- Inconel 718

- Hastelloy

Plastic

- ABS

- POM/Delrin

- PCPMMA (Acrylic)

- PEEK

- PP Polypropylene

- PTFE (Teflon)

- Ultem (PEI)Nylon

Precision CNC Milling Surface Finishes

At XY-GLOBAL, we provide 13+ precision surface finishing options to transform your CNC milled parts with a flawless finish. Choose us, choose the assuirance of uncompromising quality, optimized performance, and market-ready aesthetics.

What is CNC Milling & CNC Milling at XY-Global

CNC Milling is a high-precision, subtractive manufacturing process that utilizes computerized controls to shape solid material into complex three-dimensional parts. It is highly versatile, capable of creating flat surfaces, slots, holes, and intricate contours in virtually any material, making it ideal for prototypes and high-volume component production.

At XY-Global, we specialize in custom 3-axis, 4-axis, and 5-axis milling services, using high-end equipment like Haas and DMG MORI machines for exceptional precision and reliability. Combined with our expert machinists and rigorous quality control (QC) standards, we ensure high component quality and tight tolerances for every project—from rapid prototyping to end-use components.

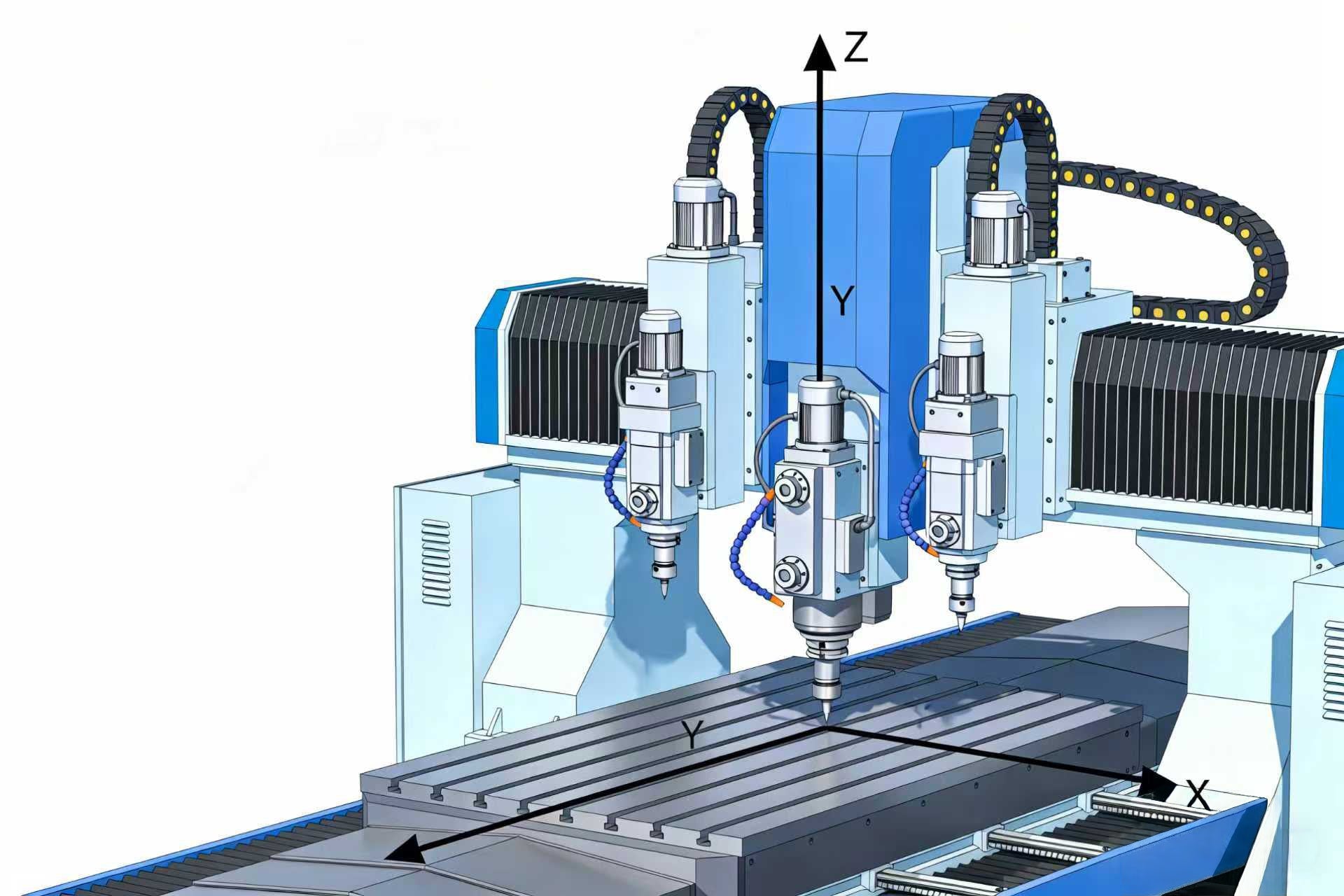

How Does CNC Milling Work?

CNC Milling is a highly precise subtractive manufacturing process that uses G-code and Computer Numerical Control to guide a rapidly rotating cutting tool to remove material from a stationary workpiece across multiple axes (X, Y, Z), producing complex 3D components with high accuracy.

The core principle of CNC milling involves the rotation of a multi-point cutting tool (such as an end mill) at high speeds, which provides the main cutting action. Unlike CNC turning where the workpiece rotates, here the workpiece is held stationary in a fixture or vise on the machine's table. The CNC controller guides the tool's precise movement along the X, Y, and Z axes to remove material, creating complex geometries and non-symmetrical parts essential for rapid prototyping and manufacturing across metals and plastics.

CNC Milling FAQs

What is the difference between CNC Turning and CNC Milling?

The key difference lies in the motion: CNC Turning involves the material (workpiece) rotating rapidly against the tool, making it highly efficient for circular parts. Conversely, CNC Milling involves the tool (cutter) rotating, which is better suited for producing complex, non-symmetric, prismatic shapes.

What are your guaranteed precision limits? What tolerances can you achieve on 5-Axis projects?

Our standard general tolerance is ±0.1mm, but with our 5-Axis capabilities, we routinely achieve tight tolerances down to ±0.025mm for critical features and materials.

What is the difference between 3-axis, 4-axis, and 5-axis machining?

The number of axes determines the degrees of freedom for the relative motion between the tool and the workpiece: 3-axis is the most basic, suitable for simple, flat parts; 4-axis adds one rotary axis, suitable for cylindrical parts or features around an axis; 5-axis has three linear axes and two rotary axes, allowing processing from more angles, completing complex geometries in a single setup, and achieving higher precision.

How do you ensure consistent quality across large production runs?

We adhere to ISO 9001 standards and employ advanced quality control, including Coordinate Measuring Machine (CMM) inspection and rigorous statistical process control (SPC), guaranteeing uniformity in every batch.

What are the Main Applications of CNC Milling?

CNC Milling span various high-tech industries, including rapid prototyping, the production of complex structural and engine components for aerospace and automotive sectors, the manufacturing of precision medical devices and implants, and the creation of intricate electronics enclosures and tooling/molds due to its ability to consistently produce complex, high-accuracy parts.