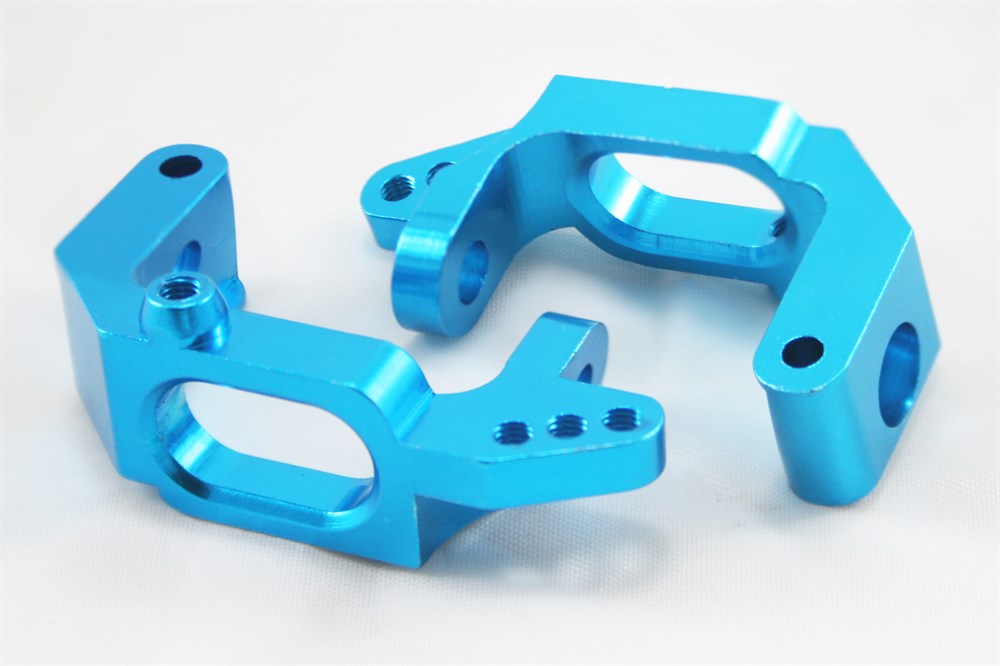

Custom Precision 5-Axis CNC Machining Services for Complex Parts

Break the limits of complex part manufacturing with our precise 5-axis CNC machining services. We deliver complex, tight-tolerance parts in a single setup, from prototypes to production.

Why Choose XY-Global for Custom Presicion CNC Machining?

When your project demands uncompromising precision and speed for complex components, XY-Global is your trusted manufacturing partner.

- Certified Precision: Achieve perfect fit and function with tolerances as tight as ±0.1um, ensured by our ISO 9001:2015 and ISO 13485 certifications.

- Accelerated Development: Turn your design files into a Rapid Prototype in as little as 1 Day, keeping your product development on the fastest track possible.

- Unrivaled Flexibility: Leverage our extensive selection of 45+ Certified Materials and 13+ Finishing options, with the freedom of a Risk-free MOQ of 1 PC.

- Guaranteed Reliability: Rest assured knowing 99% of parts are delivered on-time and to-spec, minimizing delays and maximizing your project success.

From Design to Delivery: Your 4-Step Instant CNC Machining Experience

Upload CAD Files & Receive Instant Quote

Upload your 3D CAD files to our highly secure platform and our AI-driven system analyzes geometry, material, and volume in real-time, generating a detailed final quote in under 60s.

Choose Process & Get DFM Feedback

Select your ideal material from our range of 45+ metals and engineering plastics, and customize machining options, including 3/5-Axis Milling and precise surface finishes.

Order Online & Production Kickoff

After confirming the final design specifications and quote, complete your order payment conveniently and securely on our encrypted platform. The moment payment is processed, your project task is instantly routed to our smart manufacturing facility.

Quality Control & Rapid Delivery

Every finished parts undergoes stringent, industry-leading Quality Control (QC), including high-precision dimensional checks using a CMM (Coordinate Measuring Machine) to guarantee every part meets your requested micron-level tolerances.

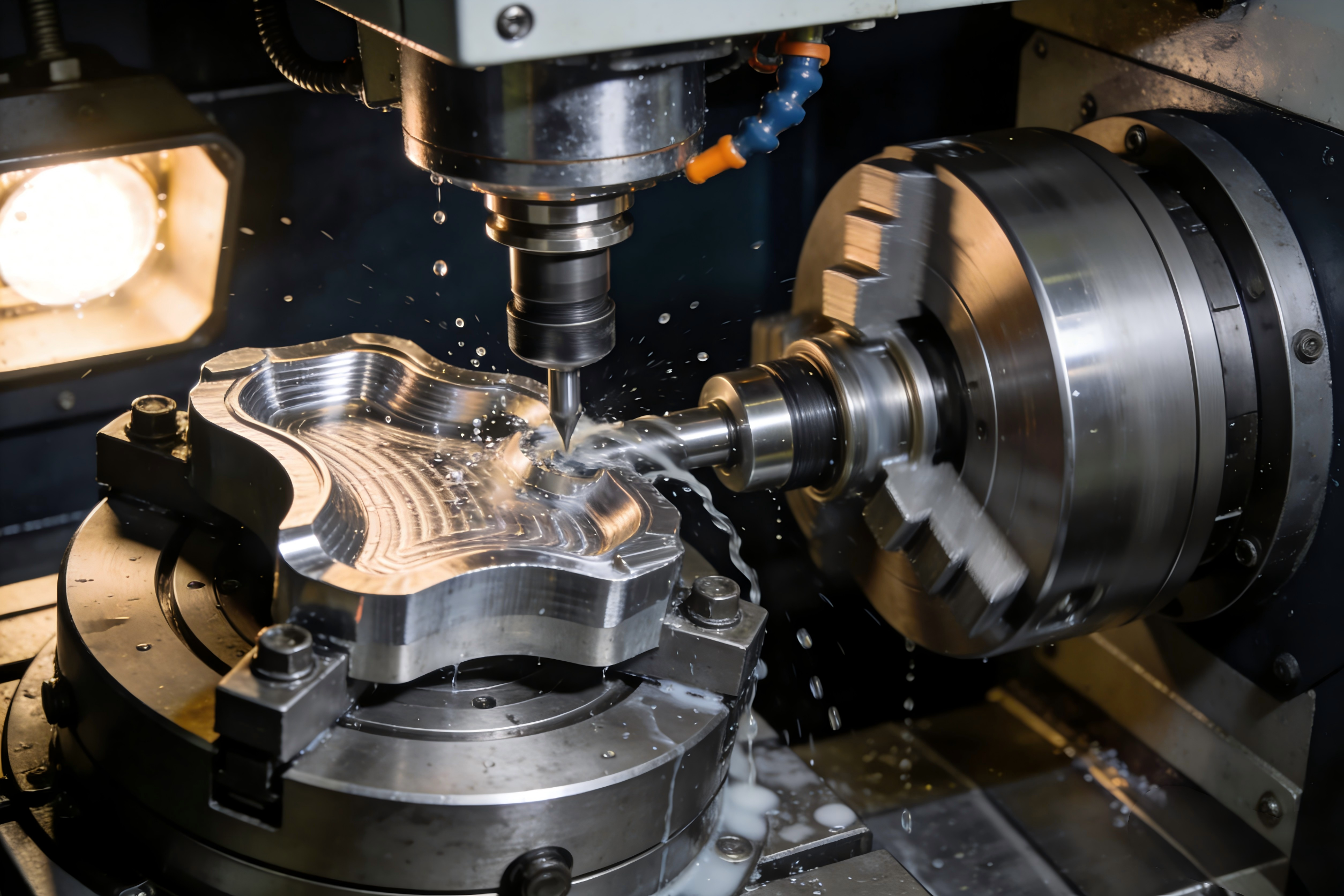

What is 5-Axis CNC Machining and How Does it Work?

5-axis CNC machining is the ultimate standard for precision in modern manufacturing. It allows a cutting tool or workpiece to move simultaneously along five distinct axes (three linear and two rotational). At XY-GLOBAL, our 5-axis CNC machining minimizes cumulative errors by completing the job in a single setup, while delivering higher precision and superior surface finish for complex parts like impellers and turbine blades.

How It Works:

Advanced CAM software coordinates the simultaneous movement of these five axes. The machine can rotate and tilt the tool and/or the workpiece, allowing the cutter to approach the part from virtually any direction. This enables machining of five faces of a complex part in a single setup.

Simultaneous 5-Axis vs. 3+2 Indexed 5-Axis Machining

1. 3+2 Indexed Machining

3+2 Indexed Machining (also known as 5-Axis Positioning) is a positioning-only mode. The machine utilizes the two rotary axes (A and B or C axes) to first lock the workpiece or tool into a specific orientation. The subsequent cutting process then proceeds solely using the three linear axes (X, Y, Z). While the cutting is not simultaneous, this method achieves a "Done-in-One" outcome, significantly mitigating the cumulative errors associated with multiple setups. It is ideal for operations like drilling, face milling, and profiling across five distinct faces.

2. Simultaneous 5-Axis Machining

Simultaneous 5-Axis Machining represents the highest level of CNC execution, requiring all five axes (X, Y, Z, and the two rotary axes) to move continuously and coordinately throughout the cutting cycle. This mode allows the tool to constantly adjust its angle relative to the part, making it the only viable method for processing complex free-form surfaces and streamlined geometries such as impellers and turbine blades. Its primary benefit is delivering superior surface finish and achieving the most stringent tolerance control.

CNC Machining Materials

At XY-GLOBAL, we go far beyond standard alloys, offering you access to a curated portfolio of 45+ certified materials, from common aluminum grades to high-performance superalloys and specialized engineering plastics like PEEK. Trust our expertise to ensure your chosen material delivers optimal performance, cost-efficiency, and certified quality.

*For materials not listed here, please contact us directly.

Aluminum

1050, 1060, 2024, 3003, 5052, 6061, 6082, 7075, 7050, A356

Stainless Steel

SUS 303, SUS 304/AISI 304, SUS 316L, SUS 440C, 17-4 PH / SUS630

Copper & Brass

C110 (Electrolytic Copper), C360 (Brass), C17200 (Beryllium Copper)

Other Metals

Titanium:

- Grade 2 (Pure Ti),

- Grade 5 (Ti 6Al-4V)

Alloy Steels:

- 4140,

- 4340

- A2/D2 (Tool Steel)

Superalloys:

- Inconel 718

- Hastelloy

Plastic

- ABS

- POM/Delrin

- PCPMMA (Acrylic)

- PEEK

- PP Polypropylene

- PTFE (Teflon)

- Ultem (PEI)Nylon

CNC Machining Surface Finishes

At XY-GLOBAL, we offer a comprehensive suite of finishing options engineered to meet the stringent demands of every industry, from providing enhanced corrosion protection for semiconductor equipment to ensuring medical-grade biocompatibility for implants.

*

We also offer custom surface finishing techniques tailored to your specific aesthetic, functional, or regulatory requirements.

3-axis vs. 5-axis CNC Machining

The primary difference between 3-axis and 5-axis CNC machining mainly lies in their production capacity and final precision.

3-axis machining operates solely along the three linear axes (X, Y, and Z). Its advantage lies in its high efficiency and lower cost for simple, flat parts, basic milling, and 2D features. Consequently, the 3-axis system is the primary choice for high-volume, foundational designs in sectors like automotive, construction, and certain aerospace components.

5-axis machining, conversely, adds two rotational axes, allowing the cutting tool or the workpiece to simultaneously cut from multiple angles. This capability makes 5-axis machines exceptionally proficient at manufacturing geometrically complex precision parts, such as impellers, turbine blades, or medical implants. While the initial investment for a 5-axis system is higher, it significantly boosts overall manufacturing efficiency and final accuracy by reducing setups and human error through its "Done-in-One" principle. Therefore, the 5-axis system is strongly preferred in sectors like aerospace, medical, and advanced automotive manufacturing, where extreme precision and tight tolerance requirements are paramount.

Upload your CAD files now for a free and precise 5-axis machining quote!

5-Axis CNC Machining FAQs

Does 5-axis machining cost more than 3-axis?

The initial cost (equipment and programming) for 5-axis is higher. However, when considering the total cost of ownership (TCO) per part, 5-axis is often more economical for complex components. It saves costs by:

- Minimizing manual setups and labor time.

- Achieving a superior surface finish, reducing or eliminating secondary finishing operations.

- Using shorter, stiffer cutting tools, which improves tool life and material removal rates.

What is the difference between 3-axis and 5-axis machining?

The fundamental difference lies in the number of simultaneous axes of motion. 3-axis machines move only along the linear X, Y, and Z axes. 5-axis machines add two rotational axes (A, B, or C), allowing the tool or part to be tilted and rotated. This added flexibility enables the cutter to approach the workpiece from virtually any angle, which is essential for machining complex, contoured surfaces.

Is 5-axis machining always required for complex parts?

Not always, but it is the most efficient and precise method. While some complex parts can be made using multiple setups on a 3-axis machine, 5-axis machining achieves the part in a single setup ("Done-in-One"). This drastically reduces accumulated setup errors, improves part-to-part consistency, and saves significant time and labor, especially for components like impellers or orthopedic implants.

What is the tolerance of 5 axis CNC machining?

While the tolerance achieved in 5-axis CNC machining varies based on factors like machine quality, material, and environment, XY-GLOBAL is capable of achieving tolerances up to ±0.002 mm for your project.

What industries benefit most from 5-axis CNC Machining?

Industries requiring high geometric accuracy and surface quality on complex parts are the primary beneficiaries:

Aerospace: Turbine blades, impellers, structural components.

Medical & Dental: Custom implants, prosthetic joints, and surgical instruments.

Energy: Oil and gas drilling tools, nuclear components.

Mold & Die: Intricate mold cavities with deep or contoured features.