Online Custom Die Casting Service

From custom tooling to finishing, and from rapid prototyping to high-volume production, XY-GLOBAL delivers high-precision die-cast components. Achieve tight ±0.01mm tolerances and thin sections down to 1.0mm with no MOQs.

XY-GLOBAL Die Casting Capabilities

| Feature | XY-Global Capability Highlights |

|---|---|

| Maximum Part Size | 900mm × 900mm (Flat parts) |

| Maximum Part Weight | Under 10kg |

| Minimum Wall Thickness | 1.0mm (depending on structure/flowability) |

| Precision Tolerance | Up to ±0.01mm (via secondary machining) |

| MOQs | No Requirement |

| Lead Time | Fastest within 7 days (varies by complexity) |

Types of Die Casting Services at XY-Global

To support diverse project requirements across industries such as medical, optical, semiconductor, and telecommunications, XY-GLOBAL utilizes two core types of die casting processes: hot chamber casting and cold chamber casting. We deliver on-demand parts featuring complex geometries and robust mechanical properties, tailored to your exact specifications. Beyond standard casting, we provide a one-stop "tooling-to-finishing" solution with high-precision secondary CNC machining to bridge the gap between raw casting and final assembly.

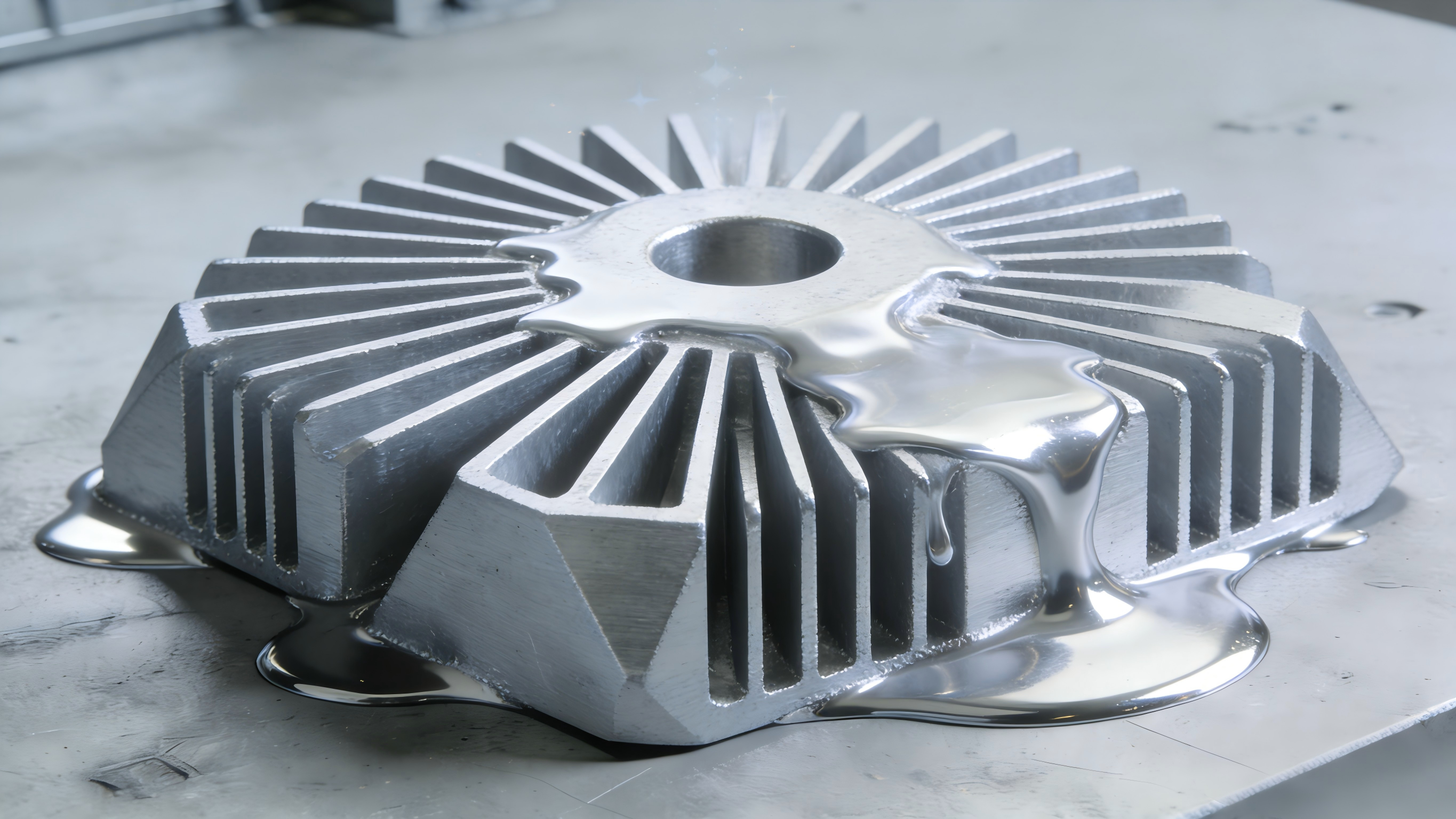

Cold Chamber Die Casting

The cold chamber process is specifically engineered for high-melting-point alloys, such as Aluminum and Magnesium, where the injection mechanism must be kept separate from the melting furnace to prevent thermal damage. In this operation, molten metal is ladled into the shot sleeve for each cycle, ensuring that the components maintain high structural density and excellent mechanical properties. At XY-GLOBAL, we operate advanced cold chamber machines with clamping forces up to 2,000 Tons. This allows us to produce large-scale structural parts with high structural density, handling dimensions up to 900mm+ for heavy-duty applications such as automotive structural components, large 5G enclosures, and industrial housings.

Hot Chamber Die Casting

Hot chamber die casting, often referred to as gooseneck casting, is the primary method for processing lower-melting-point metals such as Zinc. By keeping the injection plunger submerged in a pool of molten metal, the process achieves rapid cycle times and high production efficiency. This constant thermal equilibrium allows for the casting of highly intricate geometries and ultra-thin wall sections down to 1.0mm. Parts produced via this method typically exhibit superior surface finishes and tight dimensional stability, requiring minimal secondary polishing before cosmetic treatments like plating or painting.

Die Casting Materials and Custom Solutions

In die casting manufacturing, material selection is the core factor that dictates a product's mechanical properties and service life. XY-GLOBAL provides diverse metal casting metal materials to meet the rigorous demands of various industries. We also support custom die-cast solutions tailored to your unique engineering specifications.

Aluminum Die Casting Alloys

Aluminum is the most popular choice for modern manufacturing due to its incredible strength-to-weight ratio and excellent thermal conductivity.

- Common Grades: ADC12, A380, A360, AlSi10Mg.

- Key Benefits: Superior corrosion resistance, high operating temperatures, and lightweight properties.

- Best For: Automotive engine parts, 5G telecommunication enclosures, LED heat sinks, and aerospace components.

Zinc Die Casting Alloys

Zinc alloys are ideal for components requiring complex geometries and ultra-thin walls. They offer the easiest casting process and the longest tool life.

- Common Grades: Zamak 3, Zamak 5, ZA-8.

- Key Benefits: Exceptional dimensional stability, high impact strength, and a "jewelry-grade" surface finish perfect for electroplating.

- Best For: Intricate electronic connectors, luxury hardware, lock mechanisms, and high-precision sensors.

Magnesium Die Casting Alloys

Magnesium is the lightest structural metal available, making it the go-to material for portable devices and weight-sensitive projects.

- Common Grades: AZ91D, AM60B.

- Key Benefits: 33% lighter than aluminum, excellent vibration damping, and superior EMI/RFI shielding capabilities.

- Best For: Laptop and tablet housings, handheld power tools, and high-end camera frames.

Die Casting Surface Finishes

At XY-GLOBAL, we offer surface finishing options from anodizing and powder coating to electroplating. You can select or customize the ideal surface finish to ensure your aluminum, zinc, or magnesium parts meet the most rigorous industry standards for durability, conductivity, and visual appeal.

Powder Coating

- Offers a vast palette of colors while forming a tough, protective layer that is highly resistant to impact and corrosion;

- Effectively masks minor flow marks or surface porosity, significantly enhancing the product's tactile quality and aesthetics.

Anodizing (Type II & Type III)

- Converts the surface into an aluminum oxide layer that is extremely hard and scratch-resistant;

- Can be dyed in various colors (e.g., black, silver, gold) while preserving the natural metallic luster and texture.

Electroplating

- Provides excellent hardness and a high-gloss mirror effect, instantly transforming the alloy with a "precious metal" appearance.

Alodine

- Provides fundamental corrosion protection and serves as an excellent primer to enhance the adhesion of subsequent coatings.

Sandblasting

- Achieves a uniform matte finish. It eliminates fine flow lines and parting lines from the casting process, giving the metal surface a high-end, sophisticated texture.

Why Choose XY-Global for Custom Die Casting Services?

•Certified Precision & DFM Expertise: Achieve perfect fit and function with tolerances as tight as ±0.01mm. Our engineers provide complimentary DFM analysis to optimize your design, all backed by our ISO 9001:2015 and ISO 13485 certifications for guaranteed excellence.

• Accelerated Market Entry: Turn your CAD files into high-quality samples with our Rapid Prototyping services in as little as 1 Day. We keep your product development on the fastest track possible, from initial concept to mass production.

• Unrivaled Material & Finish Flexibility: Choose from a wide range of certified alloys and premium surface finishes. Our flexible 'No MOQ' model empowers you to transition from a single prototype to large-scale volume without limits.

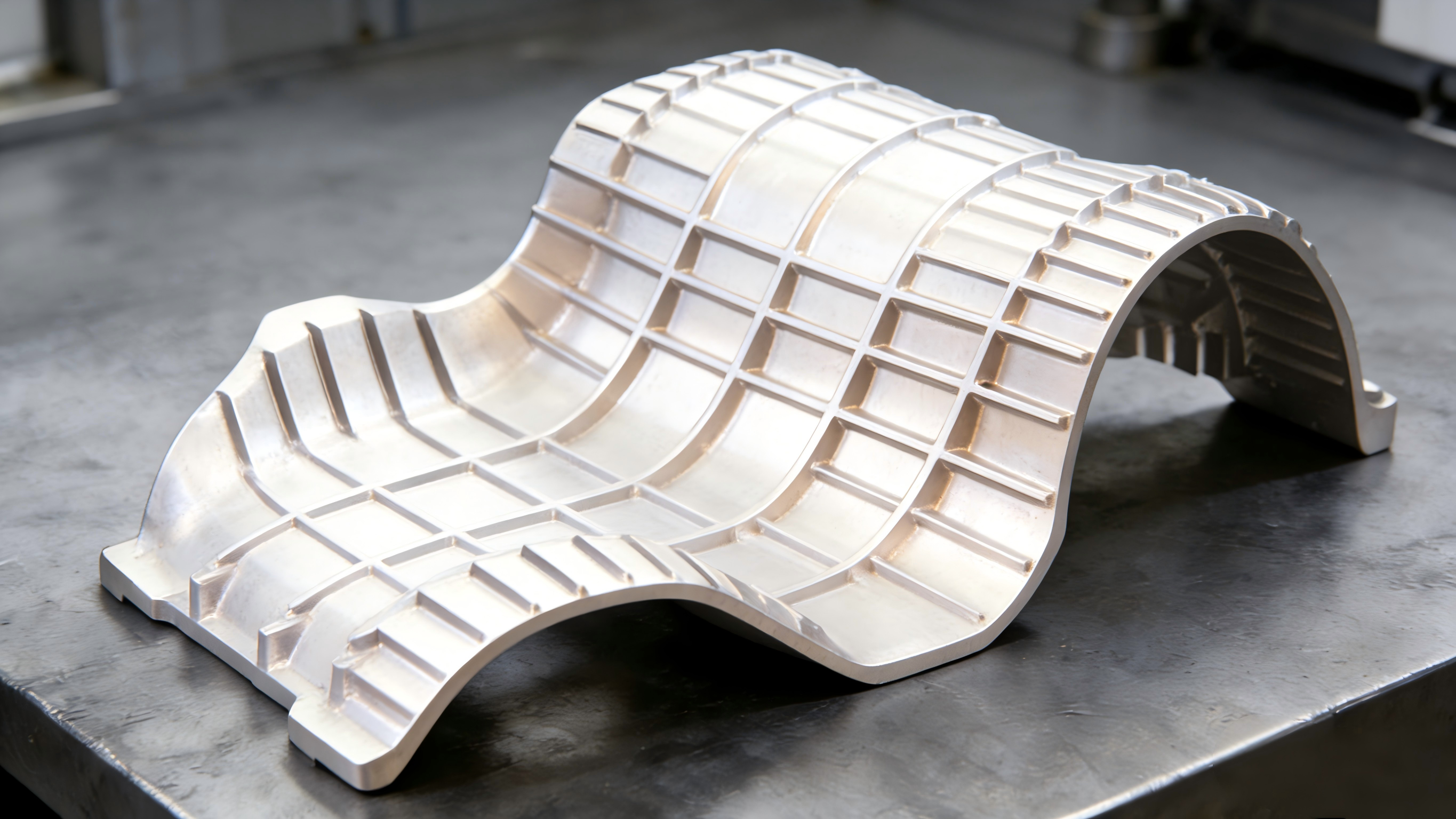

• High-Precision CNC Post-Processing: Beyond casting, we offer advanced CNC Machining capabilities to handle complex geometries and ultra-tight tolerances. Our integrated post-processing ensures every critical dimension—from threaded holes to mating surfaces—meets your exact specifications for seamless assembly.

Ready to transform your 3D models into high-performance realities? Contact our engineering experts today for a comprehensive, custom die-casting quote.

Die Casting FAQs

What is Die Casting and why should I choose it?

Die casting is a high-pressure manufacturing process that injects molten metal into a precision mold. It is the ideal choice for projects requiring high-volume production, complex geometries, and superior durability. Compared to other methods, die casting offers the best balance between speed, surface finish, and unit cost.

When should I choose die casting over CNC machining for my project?

- Die casting is ideal for high-volume production of complex parts where unit cost and speed are critical. While CNC machining is great for low-volume precision, die casting offers superior scalability and material efficiency for larger runs.

What are the advantages and limitations of die casting?

Die casting offers unmatched speed for mass-producing complex, high-strength parts with thin walls and excellent surface finishes, though it traditionally involves high tooling costs and risks of internal porosity. At XY-GLOBAL, we overcome these limitations by providing rapid tooling to reduce initial investment and utilizing advanced mold flow simulation to eliminate defects, ensuring high-precision results even for large-scale components produced on our 2,000T machinery.

How does XY-GLOBAL ensure the internal quality of complex parts?

We utilize advanced Mold Flow Analysis (Simulation) before tool fabrication. This technology allows our engineers to visualize how the metal fills the mold, helping us predict and eliminate potential defects like air entrapment or cold shuts. For critical components, we also offer X-ray flaw detection to guarantee 100% structural integrity.

What is the maximum size and clamping force you can handle?

We operate a wide range of equipment, including high-tonnage cold chamber machines up to 2,000 Tons. This enables us to produce large structural components (up to 900mm in length) for high-end industries, while our smaller machines handle intricate, high-precision electronic parts.

How do you ensure dimensional consistency over large production runs?

We use automated casting cells and regular CMM inspections to maintain ±0.01mm tolerances throughout the tool life.