Medical CNC Machining Service

Partner with XY-Global—Your ISO 13485:2016 & ISO 9001:2015 Certified Medical CNC Expert. Transform complex designs into biocompatible, high-precision components. Submit your design now, and secure safe market entry.

Medical CNC Machining Materials

In precision medical CNC machining, selecting the right biocompatible materials is critical for device safety. XY-Global specializes in machining medical-grade metals like Titanium or 316L SS and high-performance plastics such as PEEK and UHMWP for medical-specific properties.

| Material Type | Common Grades | Medical Applications | Key Machining Advantages |

|---|---|---|---|

| Medical-Grade Metals | Titanium (Ti-6Al-4V ELI), 316L Stainless Steel, Cobalt-Chrome (CoCrMo) | Orthopedic implants (hip/knee), dental abutments, surgical tool shafts |

Ti-6Al-4V ELI: Machined with low-stress processes to avoid implant fatigue 316L: Passes 500+ autoclave cycles (134℃, 2bar) without corrosion |

| High-Performance Plastics | PEEK, UHMWPE, PPSU | Spinal fusion cages, catheter fittings, hearing aid components |

PEEK: Machined with no burrs (avoids tissue irritation during surgery) UHMWPE: Low-friction surface for spinal implant mobility |

XY-Global Medical CNC Machining Services

Success in medical device manufacturing demands zero compromise on quality, compliance, and precision. As a medical CNC manufacturer with 15+ years of expertise, we can deliver highly reliable medical-grade CNC machining services and solutions for global medical brands. Choose XY-Global for:

- Certified Quality Assurance: Ensure all processes and products meet stringent medical compliance requirements, strictly adhering to the ISO 13485 and ISO 9001:2015 standard.

- Exceptional Precision and Stability: Specialize in micrometer-level tolerance control (down to ±0.002mm). Utilizing full inspection by 3D Coordinate Measuring Machine (CMM) for every batch, we achieve a high yield rate of 99.9%, guaranteeing consistent product performance.

- Efficient and Reliable Delivery: Leveraging over 100 high-end CNC machines to reduce prototype lead times to as fast as 1 business day, ensuring rapid turnaround for critical projects.

Precision Medical CNC Applications

Drive your medical innovation with XY-Global's specialized 5-Axis and Swiss CNC expertise. We deliver high-reliability, ISO 13485 compliant components from biocompatible implants to complex diagnostic devices.

Surgical Instruments and Tools

These components require strict adherence to precision, corrosion resistance, and re-sterilization protocols, utilizing stainless steel and high-performance plastics.

- Minimally Invasive Surgery (MIS) Tools: Connecting shafts, end-effectors, and guide sleeves for laparoscopes and endoscopes.

- High-Precision Handles and Clamps: Complex components for ergonomically designed forceps, scissors, and bone drills.

- Catheter Fittings and Fluid Control: Various couplings, valves, and pump body components.

- Custom Trays and Positioning Devices: Precision guides for surgical instrumentation or implant placement.

Orthopedic and Long-Term Implants

These parts demand superior biocompatibility, fatigue strength, and surface finish, typically utilizing Titanium and Cobalt-Chrome alloys.

- Artificial Joint Components: Femoral stems, acetabular cups, and liners for knee and hip replacements.

- Spinal Implants: Interbody fusion cages, plates, and various fixation screws and connectors (often using PEEK and Titanium).

- Trauma Fixation: Micro-plates and screws for fracture stabilization.

- Dental Implants: Various abutments and complete implant bodies.

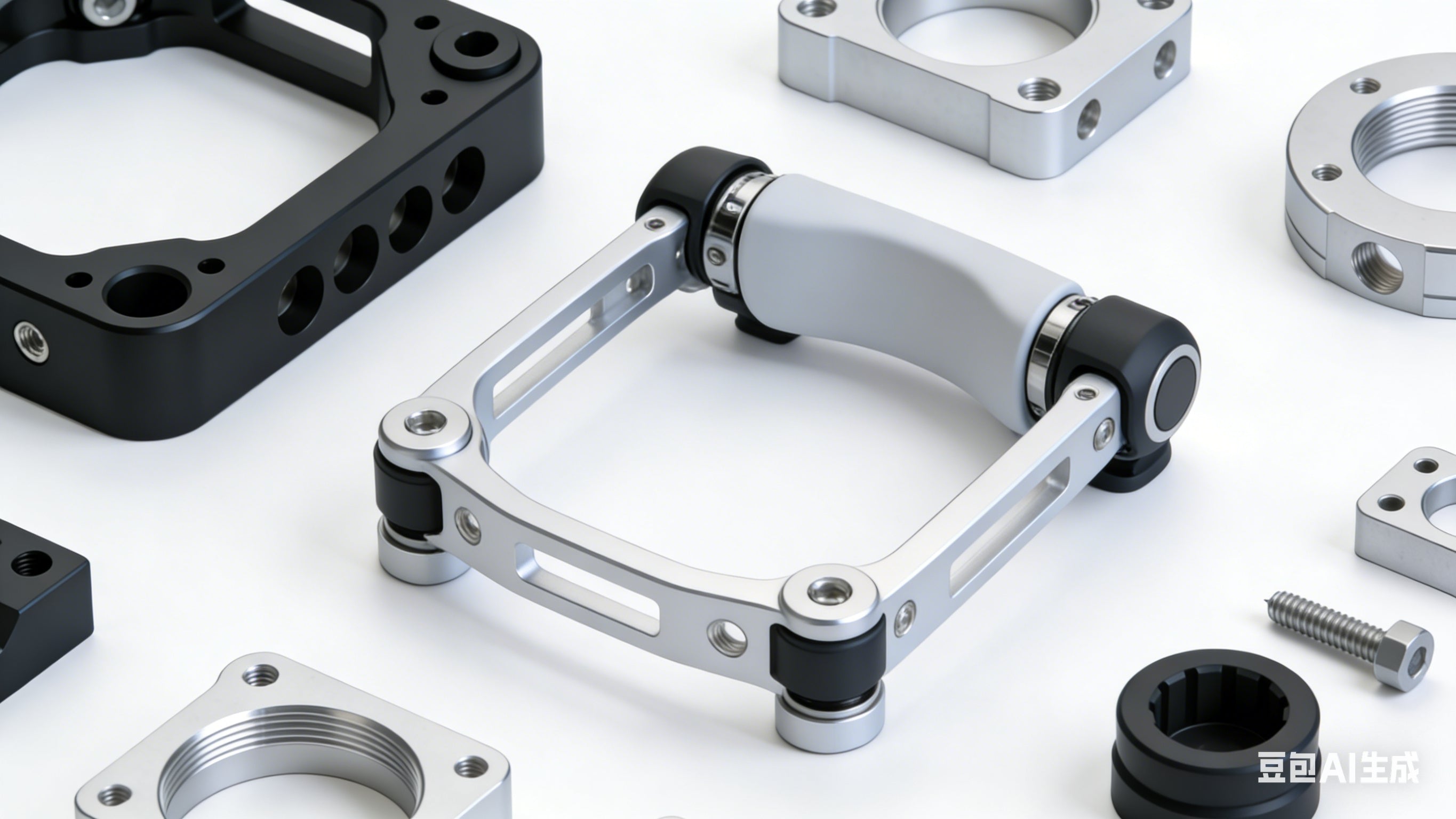

Auxiliary and Rehabilitation Equipment

These components prioritize strength, lightweight design, and cost-effectiveness, commonly using aluminum alloys and engineering plastics.

- Ventilator and Dialysis Components: Valve bodies, connectors, and fluid chambers.

- Hearing Aid Components: Micro-scale, high-precision casings and internal connectors.

- Orthotic Devices: High-strength, lightweight braces and connecting elements.

Ready to Start Your Medical CNC Project?

Medical CNC Machining FAQs

How long does it take to get a prototype for a custom medical component?

For simple designs (e.g., surgical tool handles), we can deliver prototypes in 3 business days; for complex implants (e.g., spinal cages), 5–7 business days (includes design optimization and inspection).

How do you ensure traceability for medical components?

Every component is marked with a unique serial number, linking to: ① Material batch number ② Machining operator ③ Inspection records ④ Production date. Full traceability reports are available on request.

Can you support large-volume production for medical devices?

Yes. Our production line can handle 50,000+ components/month, with automated loading/unloading systems to ensure consistency.

What is the minimum tolerance that medical CNC machining can achieve?

The standard precision for medical CNC machining is typically around ±0.005mm. For extremely critical components, specialized high-precision equipment like Swiss lathes can achieve tolerances as tight as ±0.001m.

Does your medical CNC machining comply with ISO 13485, and other industry standards?

Yes, we operate under the ISO 13485 Quality Management System.

Do you provide post-processing services (e.g., sterilization, coating) for CNC-machined medical parts?

Yes, many full-service shops provide: Passivation (Anodizing), DLC (Diamond-Like Carbon) coating, PVD coating, and more followed by sterile packaging in ISO-certified cleanrooms.