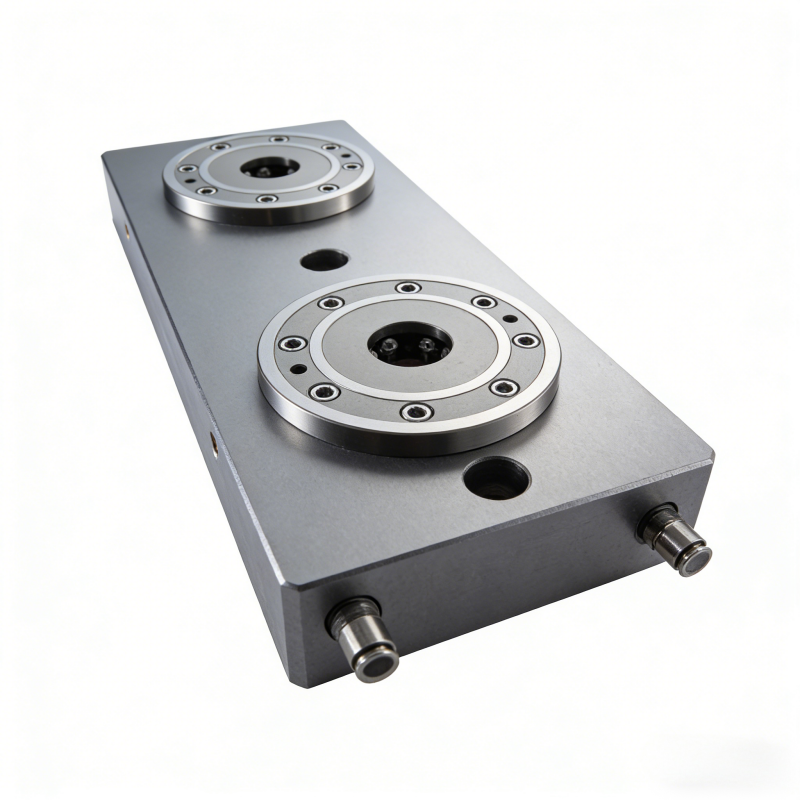

Double-Chuck Zero-Point Clamping Plate

We specialize in high-precision CNC machining and die casting, supporting tolerances down to ±0.01 mm.

Our ISO 9001 and ISO 13485 certified facilities provide in-house inspection, engineering support, and DFM review to ensure consistent quality.

We support fast prototyping to low- and mid-volume production, with strict confidentiality for all customer designs and data.

-

Contact Us

Double-Chuck Zero-Point Clamping Plate features two identical high-performance chucks integrated into one unit. This configuration is designed for users who need to process two workpieces simultaneously or require two points of contact to stabilize longer parts. It delivers the same "click-and-lock" precision as our single units but doubles your setup capability in one go.

Key Parameters (Typical)

| Item | Capability |

| Component Type | Double-Chuck Zero-Point Clamping Plate |

| Center Distance | 150mm / 200mm / 250mm (Standard) |

| Repeatability | < 0.005mm (Per Chuck) |

| Pull-in Force | Up to 15,000N per chuck (With Turbo boost) |

| Static Holding Force | Up to 35kN - 50kN (Per Chuck) |

| Lifting Capacity | 150kg pallet lift-off per chuck / 1mm point contact |

| Material | Hardened Stainless Steel / Tool Steel |

| Actuation Pressure | 6 bar(0.6MPa) (Pneumatic) |

| Surface Hardness | 58 - 62 HRC |

Key Advantages

-

Dual-Station Efficiency: Load two workpieces or fixtures in a single machine cycle, doubling output without increasing spindle runtime.

-

Synchronized Clamping: Both chucks are actuated simultaneously via a single pneumatic connection, ensuring balanced, fast locking and release.

-

Anti-Rotation Stability: The two chucks work together to form a rigid positioning axis, preventing workpiece rotation or vibration during heavy-duty side milling—no additional anti-rotation fixtures required.

-

Point-Contact Self-Cleaning: Each chuck retains a 1mm ground clearance, keeping the entire dual-interface free of chips and debris for consistent high precision.

Typical Applications

-

Tandem Machining: Process two identical or different parts at the same time, reducing tool change frequency and batch production lead time.

-

Long Part Support: Provide dual-point stability for slender plates or large mold bases, eliminating deflection during machining.

-

Horizontal Machining: Ideal for mounting on the base of Horizontal Machining Centers (HMCs) to maximize part processing density.

-

Automated Pallet Handling: Standardized dual-point interface is compatible with mainstream automated pallet systems, enabling larger, more stable robotic handling for lights-out production.