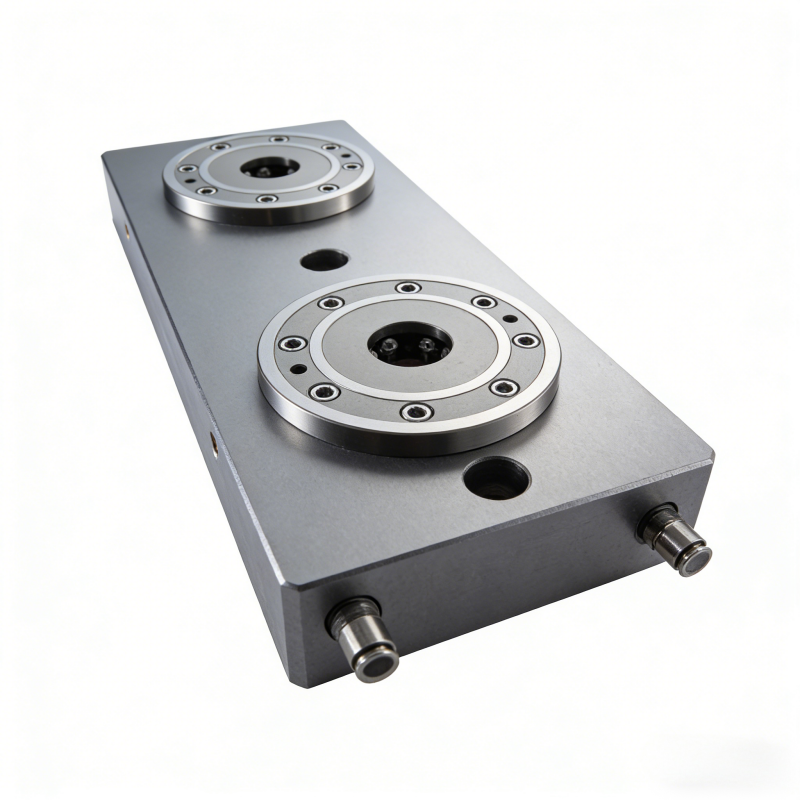

Zero Point System

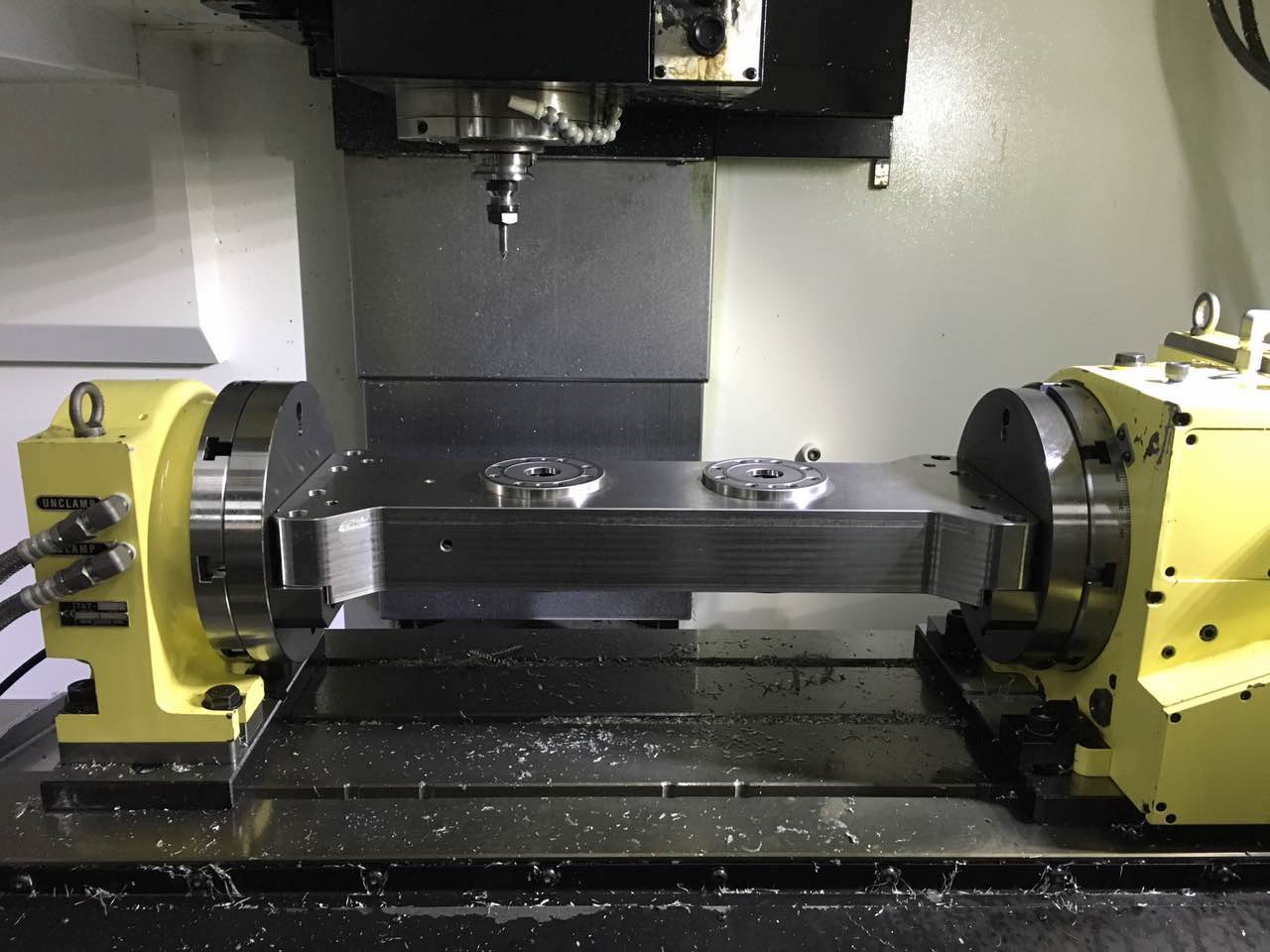

Break the limits of traditional clamping with XY-Global’s Zero Point System. Designed to replace outdated T-slot tables, our Zero-point Positioning System is easy to use and cuts setup and changeover times by 95%+, turning hours of downtime into minutes of high-output machining. Achieve a flawless <0.005mm repeatability and seamless modular flexibility. It is the core solution for any facility looking to minimize costs, maximize equipment uptime, and master rapid fixture changeovers.

So Easy to Use, From 2 Hours to 3 Minutes, Turn Downtime into Dollars 😊

Technical Advantages of Zero Point System at XY-GLOBAL

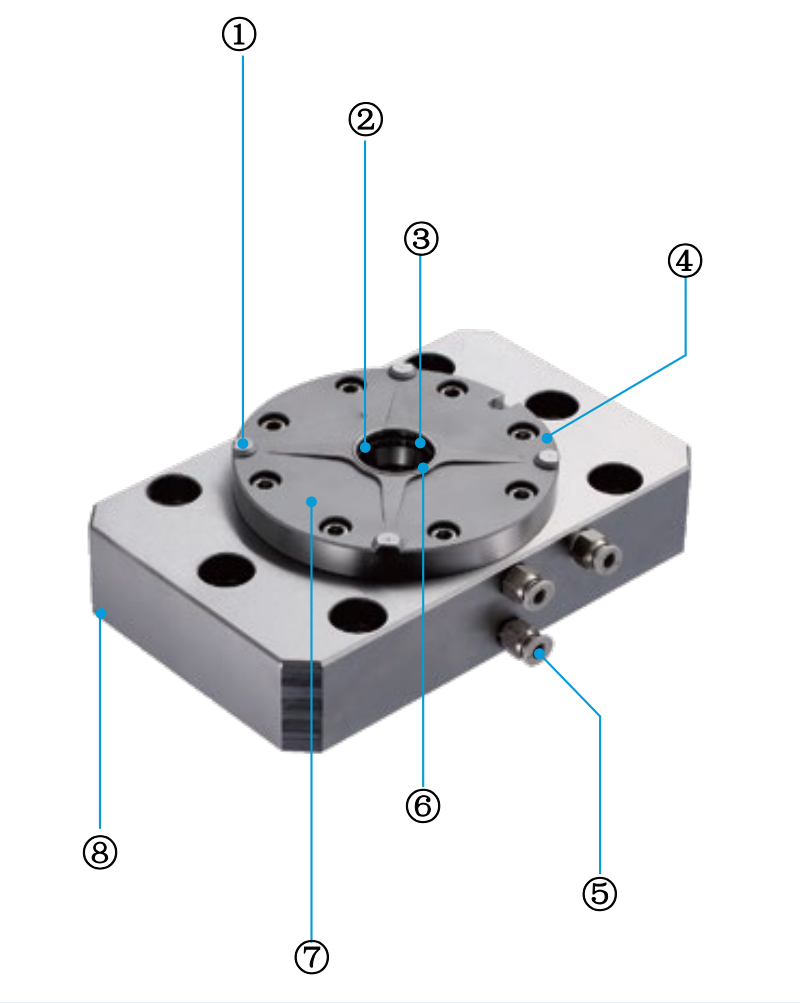

① Z-datum Functionality: Z-datum with cleaning and inspection function.

② Positioning Precision: Flexible tapered surface, precise positioning, and repeat positioning accuracy < 0.005mm.

③ Safety & Reliability: The tightening force comes from mechanical self-locking to maximize safety and reliability.

④ Physical Footprint: Compact design with minimal external dimensions.

⑤ Pneumatic Performance: Combined pneumatic function where the chuck unlocks and lifts the pallet or workpiece; 6bar air pressure can increase lift by up to 150kg for 1mm.

⑥ Contamination Control: Raised collar reduces contamination of the chuck.

⑦ Material Durability: Stainless steel construction, suitable for milling, turning, grinding, EDM machining, and all kinds of lathe work.

⑧ Clamping Power: Pneumatic turbocharger function with a maximum tightening force of up to 15,000N.

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.